I was excited to do more work on my bike. Today I spent about four hours continuing to take apart the engine. And later I told Nikola that wrenching is a kind of moving meditation--you get in a zone of mindfulness and the work is quite satisfying. I enjoy gauging the bolt sizes to find the appropriate sized tool. And if the bolt is in a weird place, brainstorming a fix for that, whether it is an extension or adapter for the wrench, or a totally different strategy. The processes are very logical and results-oriented. Wrenching is a kind of mechanical meditation and an engagement of the heart mind and physical selves and breath (can you tell I've done yoga). I envision me and Nikola riding around the island on a Sunday morning, while Buddhi is at doggy playcare.

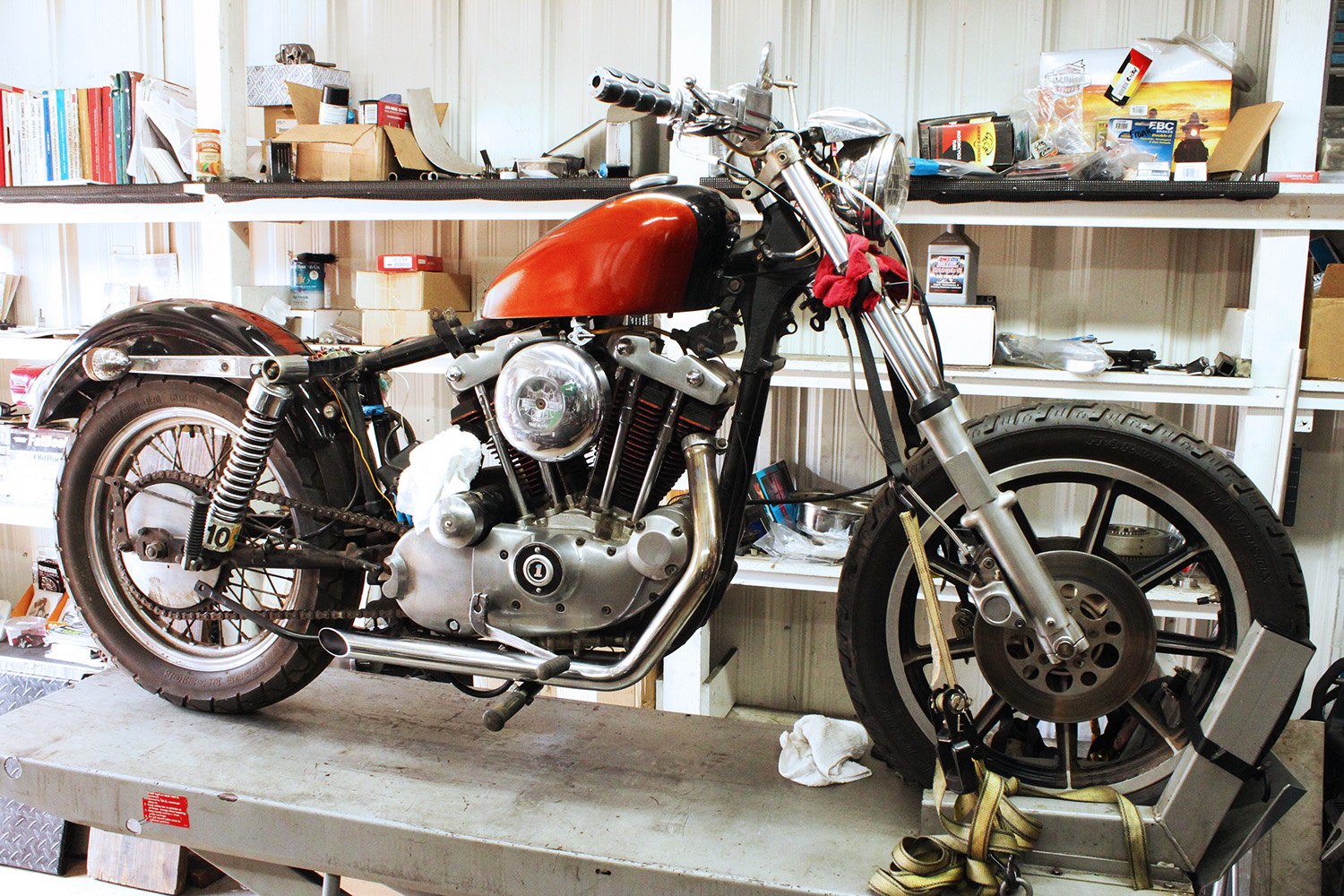

Initially when we brought the bike to the shop, it was clear it needed lowering so I could be flat footed. But some how it's turned into a much larger project of rebuilding the engine. I won't do it all from scratch, but I want to make sure that the insides are good. And I want to see all of the insides.

Except for several stripped bolts, the engine is looking pretty clean, which is a good sign.

The rear rocker box; two bolts sit directly under the frame which prevent me from simply loosening the bolts and lifting it off. (The front rocker box sat much lower under the frame so it was easy to unbolt and remove.)

I was hopeful that these two bolts would clear the frame but I quickly discovered they would not. Therefore I had to remove both the rear rocker box and rear head. First I loosened the rear rocker box bolts just enough so there was a bit of give. Then I loosened the bolts to the head (the black ridged component that sits directly underneath the silver rocker box). The head bolts were probably the heaviest I have come across so far--they are usually tightened to about 65 lbs or so. I needed some help and leverage for the initial loosening of the head bolts.

The head and the four heaviest bolts. The two springs sitting diagonally are called valve springs. Both heads are constructed of iron—cast iron. Thus the engine name, Ironhead.

The cylinder, which sits directly under the head. Inside the cylinder is the piston which moves up and down.

I rotated the back tire to turn the engine so both pistons would rise to prevent debris from falling into the cylinders.

I put towels over the cylinders.

Points which govern the timing for the ignition.

The mechanical advance unit.

The mechanical advance unit, points cam, and bolts.

Nikola took these while I loosed the allen bolts to the cam cover

The cam cover was stuck on, so giving it a few taps with a mallet was necessary before it could be pulled off.

Lovely gears!

This engine has four cams. From left to right: rear exhaust cam gear, rear intake cam gear, front intake cam gear, front exhaust cam gear.

Underneath the rear intake gear is the pinion gear, and to the right of front exhaust cam gear is the idler gear. The gear at the top right is the generator drive gear.

Timing marks on the cam gears—the gears need to line up according to these marks so all the valves open at the right time.

Here's a photo recap of parts I took off today:

I. Rear push rods and covers, and the shifter.

II. Rear rocker box and head.

III. Cam cover and the points cover, case, and panel.

Where has the engine gone? It's in pieces on my lift :-)