It's been months since I've last written and worked on my bike; it was a busy end-of-the-summer finishing up other projects on my plate. I am happy to finally be able to give some TLC and attention to my Ironhead.

(There may be gaps between what I last wrote and this post. That is the biggest challenge here--having time to work on the bike AND photo-document each step in the work as it takes more time when a camera is involved. So if you are reading this, I thank you for accompanying me on this journey, gaps and all.)

Today I adjusted the pushrods (the term is "adjusting pushrods" but technically, it is the lifters that are adjusted), which was the final task in buttoning up my motor. The pushrods have an important function in the engine--they open and close the valves, which is part of the engine combustion process.

These four vertical pipe-looking things are the pushrod covers. The pushrods are housed in the tubular steel covers you see here. Inside the covers are the pushrods which connect to lifters, which are at the bottom of the pushrods and sit above the cams (the cams engage a wheel at the bottom of the lifter, which make the pushrod go up and down).

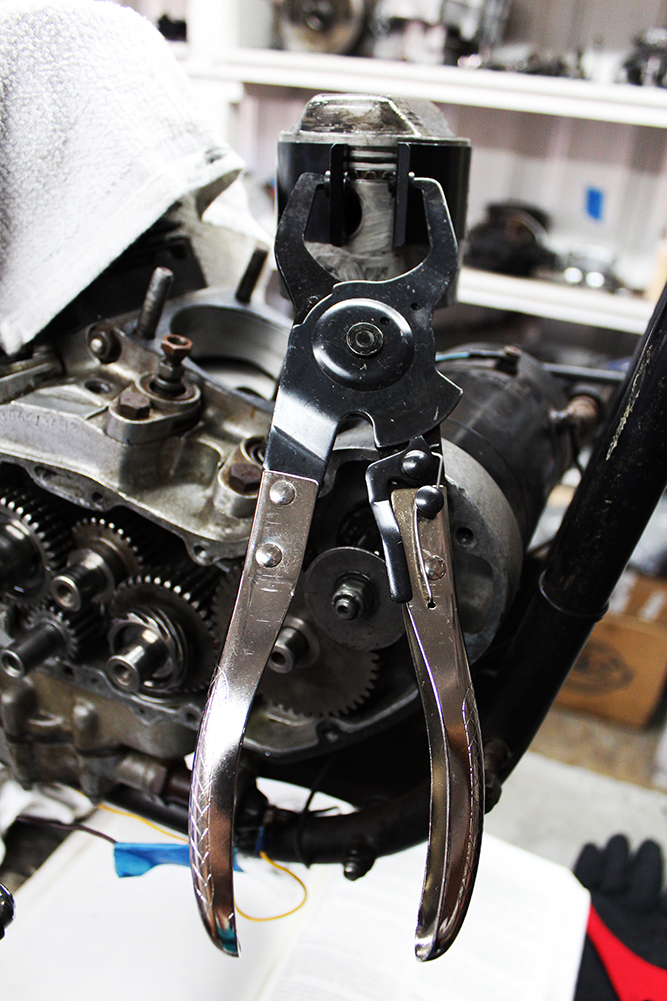

Again, cutting-edge toolery holding up the pushrod cover--you can see the pushrod here. The lifter, at the bottom of the pushrod, is what needs to be adjusted. The motor must be turned until the lifter is at the lowest position. First the lifter bolt is loosened so the pushrod has a lot of play. To adjust the pushrod the lifter bolt is tightened enough so that the pushrod has no up and down play and spins freely, completely around. Sounds easy enough?! And sure, sweaty forehead and armpits and numb fingers later, all of them have been adjusted.

Then, the pushrod cover spring retainer is put back by simultaneously pushing down on the pushrod cover and pushing in on the spring retainer.

One down--

And another one--

And there you have it. Engine is pau. (For those of you not familiar with the word 'pau')